Professional Alloy Wheel Powder Coating

- Guangdong, China

- 600 Tons per Month

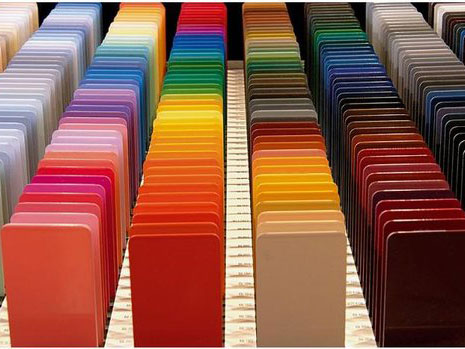

Thermosetting polyester powder coating is made by using high quality polyester and TGIC. It has various products such as high light, half light, metal effect, art, wrinkles and so on.

The powder coating has excellent weather resistance and chemical resistance, high mechanical strength and tenacity of coating.

Surface coatings for electrical equipment, heating and ventilation equipment, iron wheels, automobile spare parts, agricultural machinery, engineering machinery, office equipment, air conditioners, external decoration materials, mobile houses and other exposed facilities.

Supply Ability :600 Ton/Tons per Month powder coating polyester epoxy for indoor and outdoor

Packaging Details

Outer packing: cartons for powder coating polyester epoxy for indoor and outdoor.

Inner packing: 2 layer polyethylene bags for powder coating polyester epoxy for indoor and outdoor.

Port:Guangdong port

Lead Time:

Quantity(Kilograms)Sample 2 - 10000 10001 - 20000 >20000

Est. Time(days) 7 15 20 To be negotiated

| Thermosetting polyester powder coating | ||

| Product Profile | CP-03 Thermosetting polyester powder coating is made by using high quality polyester and TGIC. It has various products such as high light, half light, metal effect, art, wrinkles and so on. | |

| Characteristic | The coating has excellent weather resistance and chemical resistance, high mechanical strength and tenacity of coating. | |

| Applicability | Surface coatings for electrical equipment, heating and ventilation equipment, iron wheels, automobile spare parts, agricultural machinery, engineering machinery, office equipment, air conditioners, external decoration materials, mobile houses and other exposed facilities. | |

| Theoretical coverage | 10-12㎡/kg,(Film thickness 60 ų ṃ, with the state of the workpiece, coating method, coating conditions, all the differences) | |

| Dry storage stability | 12 months (less than 30 ℃) | |

| Pretreatment | In order to achieve the ideal adhesion, it is suggested that the substrate should be properly pretreated before coating, and different pretreatments should be adopted for different substrates | |

| 1. Zinc phosphating (improving corrosion resistance and adhesion) | ||

| 2. Iron phosphating (improve corrosion resistance and adhesion) | ||

| 3. Chromizing treatment (improve the adhesion between coating and aluminum substrate) | ||

| Curing process | 1. Low temperature curing 160 ℃ @ 25min (MT) | |

| 2. Conventional curing 180 ℃ @ 15min (MT) | ||

| 3. Rapid curing 200 ℃ @ 10min (MT) | ||

| Construction method | Electrostatic and friction gun spraying, manual and automatic. Metal flash powder can only be applied with electrostatic coating, and arts and crafts powder is recommended to use automatic gun spraying to ensure uniform color and appearance effect. | |

| Main technical specifications | ||

| Item | Test standard | Index |

| Gardner60 º gloss | ASTMD523,ISO2813,GB/T9754-18 | Gloss between 10-95% as per customer requirements |

| Scribble adhesion | ASTMD3359,ISO2409,GB/T1185-98 | Grade 0 |

| Bending test of shaft bar | ASTMD522,ISO1519 | 3mm |

| Impact resistance | AS3715 2.8,GB/T1732-93 | 30-50kg.cm |

| Cupping test | ISO1520 | 4-7MM |

| Pencil hardness | GB/T6739-98 | 1H-2H |

| Salt fog resistance | ASTMB117-87,GB/T1771-91 | The maximum scratch corrosion after 600H test is 1mm |

| Heat and humidity resistance | ASTMD2247-87,GB/T17740-89 | Maximum blister 1mm after 500h test |

| QUV artificial accelerated aging | 400h | No powdering, light retention > 80%, color change less than munsel1 |

| Resistant to 10% HCI | 240h | No bubbles, no surface damage |

| Resistant to 10% NaOH | 240h | No bubbles, no surface damage |

Can be customized according to customer requirements