Wrinkle Finish Electrostatic Epoxy Polyester Powder Coating

Being a reliable manufacturer and supplier, we offer pure polyester resin powder coating to our clients. It is a fine mix of saturated carboxyl polyester resins as well as TGIC. We offer great interior and exterior finish. In accordance to set industrial standards, our offer range is available in wide assortment so that our clients can choose the product as per their requirement and need.

Polyester resin powder coating is the most used of all powder coatings in the worldwide market. Polyester's offer a broad application field and many different chemistries including: Polyester/TGIC (triglycidyl isocyanurate); Polyester/TGIC-free; Super-durable Polyester and Polyester Hybrids.

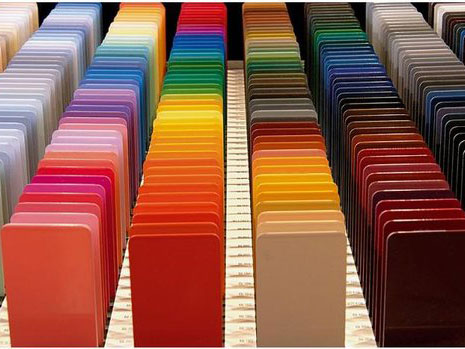

A variety of Polyester resin powder coating is provided by us at industry leading prices. These have superb flow and finish which impart brightness to the painted object. Apart from that, this product also has superior mechanical properties like temperature resistance and corrosion resistance. This product is available in many colors and in gloss, matt and texture finishes.

| Thermosetting polyester powder coating | ||

| Product Profile | CP-03 Thermosetting polyester powder coating is made by using high quality polyester and TGIC. It has various products such as high light, half light, metal effect, art, wrinkles and so on. | |

| Characteristic | The coating has excellent weather resistance and chemical resistance, high mechanical strength and tenacity of coating. | |

| Applicability | Surface coatings for electrical equipment, heating and ventilation equipment, iron wheels, automobile spare parts, agricultural machinery, engineering machinery, office equipment, air conditioners, external decoration materials, mobile houses and other exposed facilities. | |

| Theoretical coverage | 10-12㎡/kg,(Film thickness 60 ų ṃ, with the state of the workpiece, coating method, coating conditions, all the differences) | |

| Dry storage stability | 12 months (less than 30 ℃) | |

| Pretreatment | In order to achieve the ideal adhesion, it is suggested that the substrate should be properly pretreated before coating, and different pretreatments should be adopted for different substrates | |

| 1. Zinc phosphating (improving corrosion resistance and adhesion) | ||

| 2. Iron phosphating (improve corrosion resistance and adhesion) | ||

| 3. Chromizing treatment (improve the adhesion between coating and aluminum substrate) | ||

| Curing process | 1. Low temperature curing 160 ℃ @ 25min (MT) | |

| 2. Conventional curing 180 ℃ @ 15min (MT) | ||

| 3. Rapid curing 200 ℃ @ 10min (MT) | ||

| Construction method | Electrostatic and friction gun spraying, manual and automatic. Metal flash powder can only be applied with electrostatic coating, and arts and crafts powder is recommended to use automatic gun spraying to ensure uniform color and appearance effect. | |

| Main technical specifications | ||

| Item | Test standard | Index |

| Gardner60 º gloss | ASTMD523,ISO2813,GB/T9754-18 | Gloss between 10-95% as per customer requirements |

| Scribble adhesion | ASTMD3359,ISO2409,GB/T1185-98 | Grade 0 |

| Bending test of shaft bar | ASTMD522,ISO1519 | 3mm |

| Impact resistance | AS3715 2.8,GB/T1732-93 | 30-50kg.cm |

| Cupping test | ISO1520 | 4-7MM |

| Pencil hardness | GB/T6739-98 | 1H-2H |

| Salt fog resistance | ASTMB117-87,GB/T1771-91 | The maximum scratch corrosion after 600H test is 1mm |

| Heat and humidity resistance | ASTMD2247-87,GB/T17740-89 | Maximum blister 1mm after 500h test |

| QUV artificial accelerated aging | 400h | No powdering, light retention > 80%, color change less than munsel1 |

| Resistant to 10% HCI | 240h | No bubbles, no surface damage |

| Resistant to 10% NaOH | 240h | No bubbles, no surface damage |

| Can be customized according to customer requirements | ||